Advantages over conventional materials

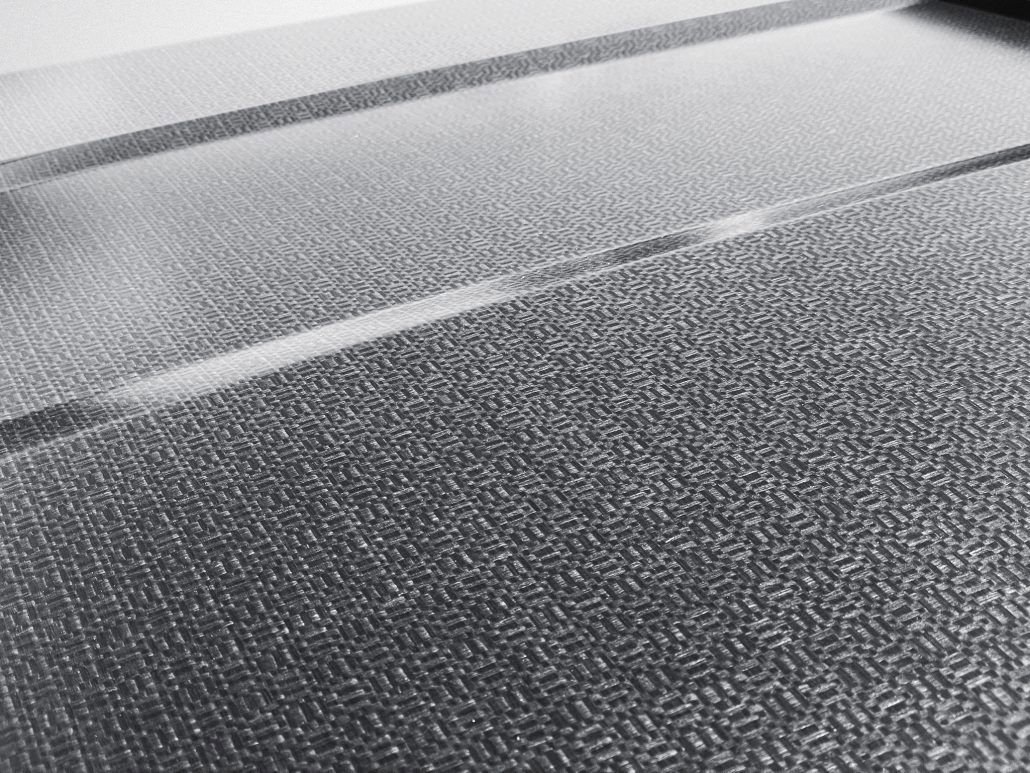

Flax-based natural fiber composites offer several advantages over traditional composites such as carbon fiber or plastic. Not only are they lighter, they are also significantly more sustainable. According to BMW, the use of these natural fibers reduces CO₂e emissions in the manufacture of roof components by around 40 percent—a reduction that covers both production and the end of life of the component.

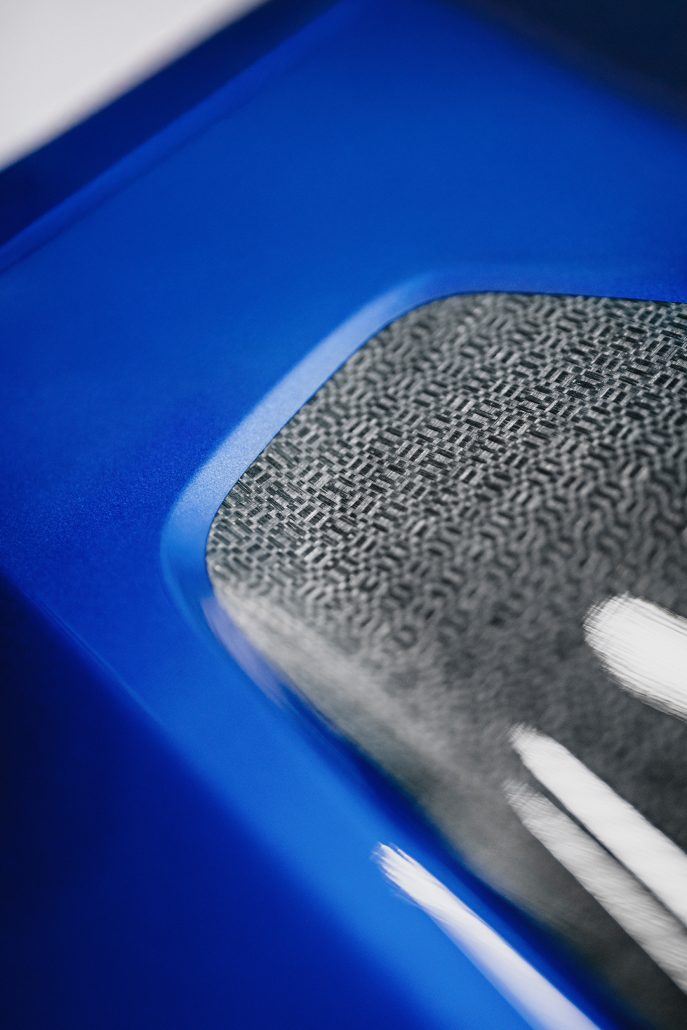

The CO₂e savings are calculated based on internal calculations and practical experience from motorsport. These natural fiber composites were first used in Formula E in 2019 and have been continuously developed since then. In models such as the BMW M4 DTM and M4 GT4, they have already successfully replaced parts made of carbon fiber reinforced plastic (CFRP).

Motorsport as a development platform

Consistent use in motorsport not only serves as a practical test, but also accelerates material development. Since 2022, Bcomp has been an official BMW M Motorsport partner, particularly for the BMW M4 GT4, which is considered the ultimate stress test for the new materials at the 24-hour race at the Nürburgring. Franciscus van Meel, Managing Director of BMW M GmbH, emphasizes:

“Natural fiber composites make an important contribution to innovative lightweight construction solutions in motorsport and enable a reduction in CO₂e emissions in the manufacturing process. Natural fiber is an innovation that embodies the BMW M philosophy ‘Born on the racetrack. Made for the streets.’”

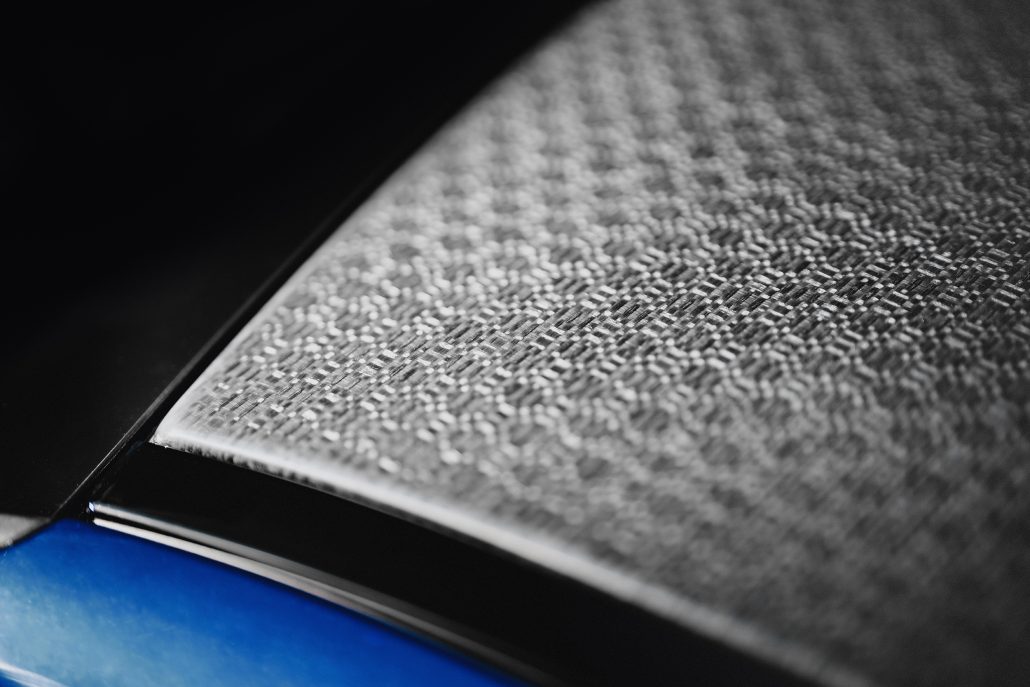

Prospects for large-scale production and two-wheelers

Following successful testing in motorsport, the technology is now finding its way into series production – initially in passenger cars, but according to current estimates, its use in motorcycles is also likely to follow soon. The BMW Group has a direct stake in Bcomp via BMW i Ventures in order to further advance development.

The introduction of flax composites in series production underscores the company’s commitment to further reducing its CO₂e footprint while offering innovative lightweight solutions. In addition to BMW, other manufacturers such as Honda and Royal Enfield have also recognized the potential of natural fibers: While Honda already uses the bioplastic Durabio in the NC750X, Royal Enfield is said to have plans for flax-based body parts in an electric version of the Himalayan.

Ecological and technical advantages at a glance

Flax, the basis for these materials, is not only environmentally friendly to grow, but also characterized by its low weight and high strength. In addition to the ecological benefits, there are also tangible technical advantages, such as weight: lighter components help to reduce fuel consumption and improve dynamics. The weight savings are noticeable in both automobile and motorcycle construction, especially with increasingly heavier models.

A conversion of typical components illustrates the savings potential: for example, if a conventional carbon fiber roof weighs 5 kg (about 11 lbs), a comparable natural fiber component with the same strength could weigh about 4 kg (around 8.8 lbs). This results in significant savings per vehicle.

Conclusion: Innovation that sets an example

With the series production of flax-based natural fiber composites in vehicle manufacturing, the BMW Group is sending a clear signal for sustainable innovation. The combination of ecological advantages, technical performance, and practicality makes this development a significant step toward sustainable mobility solutions for the future.

- Abus 79270Abus 8008 Granit Detecto XPlus 2.0 (79270) Silber