Bosch relies on metal 3D printing

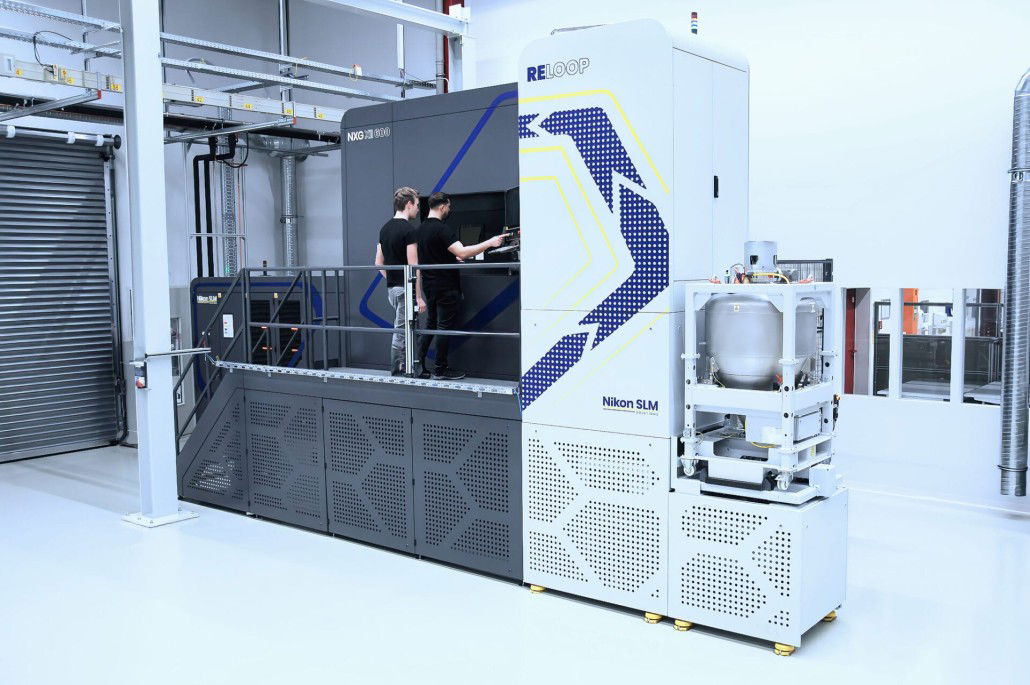

The technology group Bosch, known for its key role in the automotive and motorcycle world – from ABS systems and injection technology to control electronics – is investing heavily in additive manufacturing. This refers to industrial metal 3D printing, in which powerful lasers are used to fuse metal powder layer by layer into high-strength components. This process makes it possible to create complex geometries that would be difficult or impossible to produce using traditional methods such as casting or milling.

Faster from the idea to the finished part

A key advantage of metal 3D printing is the drastically reduced development time. While conventional manufacturing methods often take weeks to produce prototypes – including toolmaking and material waste – engineers can print, test, adapt and produce components again in just a few days. This not only saves time, but also costs.

Lighter, stronger, more intelligently designed

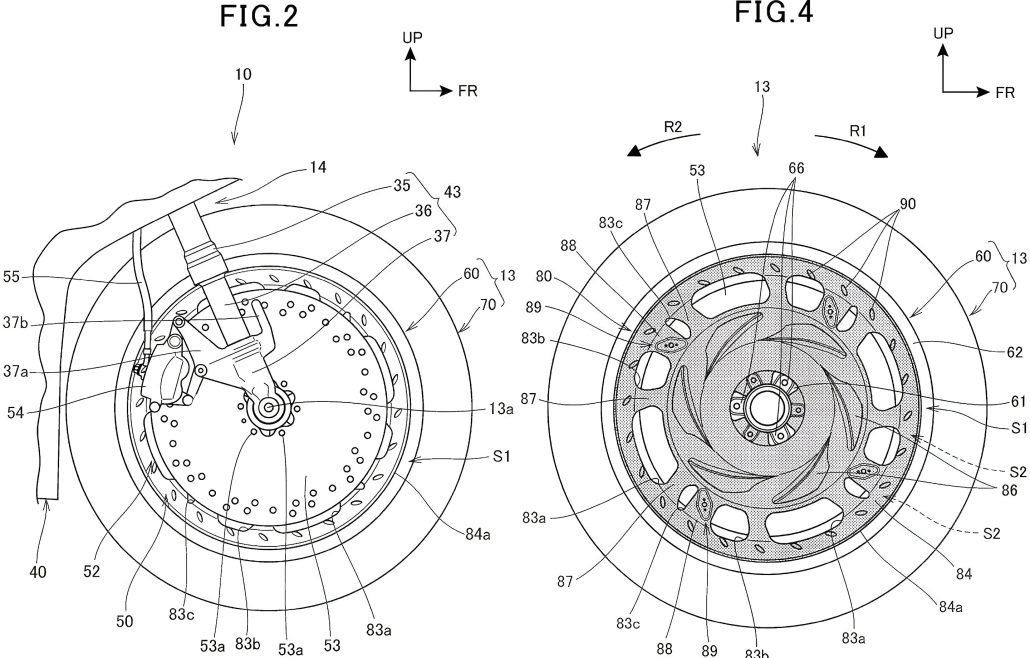

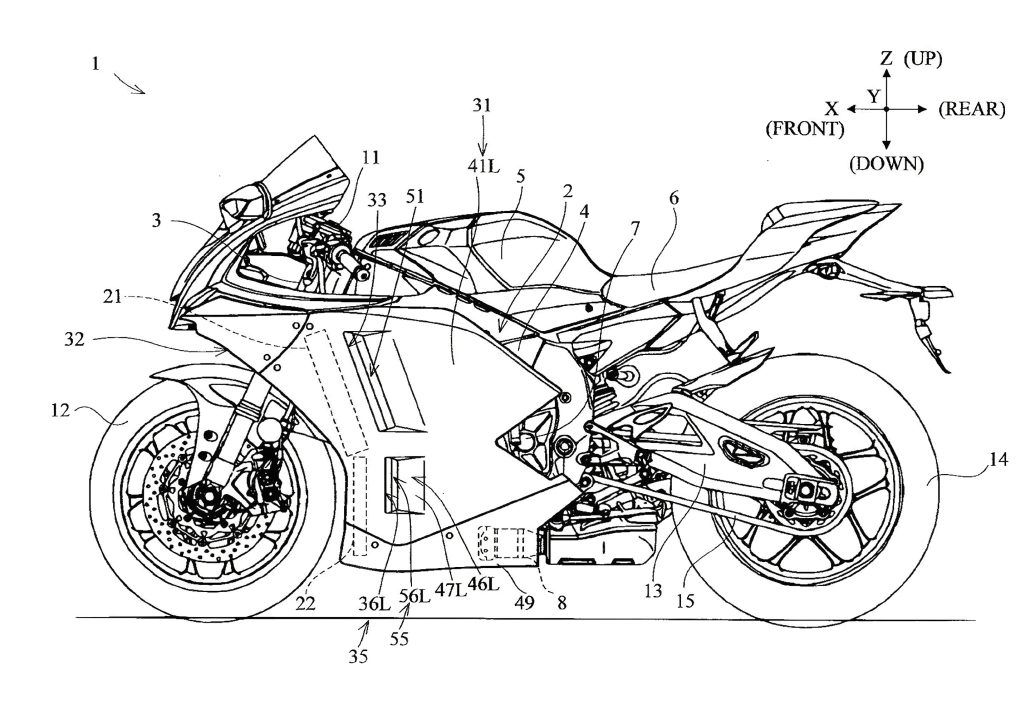

Metal-based 3D printing not only opens up new freedoms in design, but also makes it possible to optimize weight and strength. For example, frames with integrated flex zones for better handling, ultra-light engine components or innovative brake parts with improved heat dissipation are all conceivable. Additive manufacturing makes it possible to design components in such a way that they are precisely tailored to their load – material is only used where it is really needed.

Consequences for the motorcycle world

Bosch’s commitment could have far-reaching consequences for the entire motorcycle industry – from development to production and customization. Small-series manufacturers and start-ups could benefit from lower entry costs, while established brands would be able to react more quickly to market changes or test new technologies.

It is still unclear when the first production-ready 3D-printed metal parts will be found on road motorcycles. But the potential is enormous – and Bosch seems determined to exploit it.

[amazon bestseller=”3D Druck” items=”3″]